how does a batching plant work

Product Description: Advanced Batching Plant

Product Description

Product Description: Advanced Batching Plant

Discover the cutting-edge technology behind our state-of-the-art Batching Plant – where precision meets performance! Designed for construction professionals seeking to maximize efficiency and quality, our batching plant stands as a testament to innovative engineering and customer-centric design.

How It Works

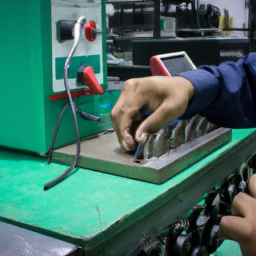

Our batching plant operates on a sophisticated automation system that meticulously measures and mixes various raw materials, such as cement, aggregates, water, and additives, to produce high-quality concrete. It employs a series of weigh hoppers and conveyor belts to ensure that the materials are accurately dosed and seamlessly blended. With a system that allows for real-time monitoring, you can trust that every batch meets your exact specifications.

Key Specifications

- Production Capacity: Up to 120 cubic meters per hour

- Mixing Time: Quick mixing cycles under 60 seconds

- Control System: Advanced PLC control with touchscreen interface

- Hopper Capacity: Each hopper can hold up to 5m³ of materials

- Aggregate Bins: Configurable with 3-5 bins for diverse material storage

- Power Supply: Energy-efficient options with minimal consumption rates

Main Advantages

High Precision:Our batching plant utilizes cutting-edge load cells and sensors, ensuring that every ingredient is measured accurately. This capability guarantees consistency in the quality of concrete produced, reducing waste and enhancing overall project performance.

Versatile Applications:Ideal for ready-mix concrete suppliers, large construction sites, or precast concrete production, our batching plant is designed to handle a wide variety of concrete mixes, catering to different construction requirements.

User-Friendly Interface:With its intuitive control panel, operators can easily set parameters, monitor production, and adjust settings to optimize performance, all in a user-friendly environment.

Robust Design:Built from high-quality materials, our batching plant is engineered to withstand heavy usage and harsh conditions, ensuring reliability and longevity – a solid investment for your business.

Customizable Solutions:We understand that each project has unique needs. Our batching plant can be customized with additional features such as a moisture measurement system, fiber dosing, and more to fit your specific requirements perfectly.

Unique Selling Points

- Efficiency Redefined: Reduce operational costs with our energy-efficient designs and rapid production capabilities.

- Scalability: As your business grows, our batching plant can be easily scaled or integrated into existing systems, ensuring your investment stands the test of time.

- Support & Service: Enjoy peace of mind with our dedicated customer support team, offering assistance and maintenance services tailored to your operational needs.

Conclusion

In a world where timelines and quality are paramount, our batching plant equips your business with the tools needed to succeed. Elevate your concrete production process and ensure every project meets the highest standards of quality and efficiency.

Don't miss the opportunity to transform your operations. Contact us today to learn more about our batching plant and request a personalized quote! Take the first step towards enhanced productivity and superior results – we’re here to support you every step of the way!

Related Products:how does a batching plant work, stationary asphalt mixing plant sale