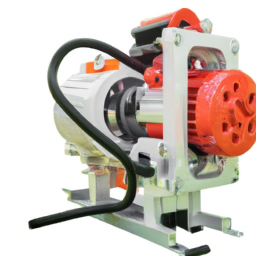

idler roller types

Introduction:Introducing our premium Idler Rollers, engineered for versatility and efficiency in various industrial applications

Product Description

Product Description for Idler Roller Types

Introduction:Introducing our premium Idler Rollers, engineered for versatility and efficiency in various industrial applications. These rollers are designed to support conveyor systems, enhancing material handling while ensuring smooth operations. With a robust construction and an array of specifications tailored to meet diverse needs, our idler rollers stand out as a reliable choice for businesses seeking quality and performance.

Key Features:

- Material Quality: Manufactured from high-grade steel or durable polyurethane, providing exceptional strength and resistance to wear and tear.

- Size Options: Available in multiple diameters and lengths to accommodate different conveyor systems. Sizes range from 1.5 inches to 6 inches in diameter, with lengths customizable based on specific installations.

- Load Capacity: Designed to bear heavy loads, our idler rollers can handle capacities up to 1,200 kg, making them suitable for various industrial environments.

- Technical Integration: Some models come with integrated AI monitoring systems, allowing for real-time assessment of performance and predictive maintenance capabilities.

- Performance Optimization: Offering low friction and high rotational efficiency, our idler rollers improve the speed and reliability of material transport systems, reducing downtime and operational costs.

Unique Selling Points:

- Durability: Crafted with top-quality materials to ensure long-lasting use, reducing the frequency of replacements and maintenance.

- Customizable Dimensions: Tailor-made solutions to fit seamlessly into any existing system while accommodating future upgrades.

- Smart Technology Integration: The optional AI feature empowers businesses to monitor the health of their conveyor systems, anticipate failures, and streamline maintenance schedules.

- Enhanced Efficiency: Engineered to minimize energy loss and maximize transport speeds, these idler rollers significantly contribute to overall operational efficiency.

Problem-Solving Benefits:Our idler rollers are designed to resolve common challenges faced in conveyor systems, such as friction-related wear, unexpected downtimes due to equipment failure, and inefficiencies in material handling. By integrating advanced materials and optional smart technology, businesses can not only enhance the longevity and reliability of their equipment but also improve productivity levels. Investing in our idler rollers means streamlined operations and a greater return on investment, ensuring that your business stays competitive in an ever-evolving industry landscape.

Conclusion

Upgrade your material handling systems with our state-of-the-art Idler Rollers and experience a new standard in performance and reliability. Contact us today for more information on specifications, customization options, and pricing!

Related Products:idler roller types, Piston Seal