induction brazing systems

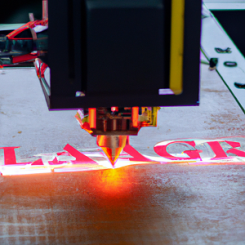

Induction Brazing Systems: Elevate Your Joining Technology

Product Description

Induction Brazing Systems: Elevate Your Joining Technology

Unlock unparalleled precision and efficiency in your metal joining processes with our state-of-the-art Induction Brazing Systems. Designed for professionals seeking remarkable performance, these systems offer a reliable and innovative solution for a wide range of applications, from automotive components to electronic assemblies.

Key Specifications:

- Power Range: Available in options from 1 kW to 50 kW, our systems cater to various production scales.

- Frequency Range: Operates at adjustable frequencies between 20 kHz to 100 kHz, ensuring optimal heating for different materials and applications.

- Cooling System: Equipped with advanced water-cooling technology to maintain optimal operating temperatures and enhance system longevity.

- User Interface: Intuitive touch screen controls with programmable settings for seamless operation and consistent results.

Main Advantages:

Precision Heating: Induction brazing provides exact heat application, minimizing thermal distortion and ensuring exceptional joint quality. This precision reduces scrap rates and saves on rework costs.

Time Efficiency: Experience rapid heating cycles that significantly decrease production times. Our systems can join parts in seconds, making your operations faster and more competitive.

Energy Efficiency: With low power consumption and reduced heat loss, our induction systems are environmentally friendly and cost-effective, lowering your operational expenses.

Versatility: Ideal for a wide range of materials — including copper, brass, and even dissimilar metals — our systems are perfect for diverse industries such as automotive, aerospace, HVAC, and electronics.

Safety and Reliability: With built-in protection features and a robust design, our inductive brazing systems ensure safe operations and minimal maintenance, allowing you to focus on your business without interruptions.

Applications:

- Automotive Industry: For joining metal components, enhancing durability and performance in engine parts, transmissions, and sensors.

- Aerospace Manufacturing: Meeting stringent standards for reliability and safety in aircraft components and assemblies.

- Electrical and Electronics: Perfect for the assembly of coils, transformers, and connectors that require precise and reliable joints.

- HVAC Systems: Efficiently braze heat exchangers and other critical components, improving system performance and longevity.

Why Choose Our Induction Brazing Systems?

Our induction brazing systems are not just tools; they are comprehensive solutions tailored to meet the diverse needs of your operations. With a focus on unmatched performance, energy efficiency, and user-friendliness, we empower you to achieve superior quality in your fabrication processes.

Don’t settle for mediocrity; elevate your production capabilities with our top-tier induction brazing systems. Contact us today for a personalized consultation and discover how our innovative technology can transform your metal joining processes!

Related Products:induction brazing systems, induction brazing tools